Providing environmentally friendly in-ground LNG storage tanks renowned for their high-level of safety

LNG tanks are employed in a variety of types throughout the world according to social needs and the site environment. Storage tanks are broken down to two categories, in-ground storage tanks and above ground storage tanks.

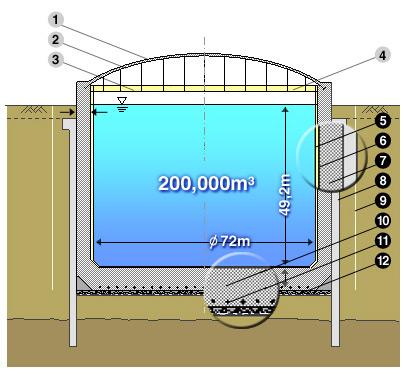

In-ground storage tanks have a high level of safety and are environmentally friendly. Japan has 76 such tanks with a capacity of 6.3 million m3. Highly regarded overseas, Tokyo Gas constructed six tanks in Taiwan to hold 690,000 m3 and ten in Korea to hold 1.88 million m3. In 1970 the first in-ground LNG storage tank was constructed with a capacity of 10 thousand m3. Since then, Tokyo Gas has constructed 37 in-ground LNG storage tanks with a total capacity of 3.3 million m3, while working at improving tanks. Currently the company is constructing state of the art in-ground storage tanks including the world’s largest underground storage tank with a capacity of 200,000 m3. Utilizing this technology and experience, Tokyo Gas is providing in-ground storage tanks suited to a variety of customer needs.

How in-ground LNG storage tanks work: Tank composition

The side wall and bottom slab of in-ground storage tanks have a multiplex structure with three layers: reinforced concrete, insulation and a membrane.

1. Since the side wall and bottom slab of in-ground storage tanks are subjected to external earth and water pressure more than internal pressure, reinforced concrete is an ideal material because of its excellent compressive strength. The tanks are specially designed to withstand earthquakes underlining their high level of safety.

2. Rigid polyurethane foam (PUF) insulation restricts the permeation of heat from outside and transfers the internal gas and LNG pressure exerted on the tank side wall and bottom slab.

3. A two-millimeter membrane layer maintains LNG and gas tightness. The membrane is corrugated to absorb contraction due to the difference in ambient temperature and LNG temperature which is minus 162 degrees Celsius,.

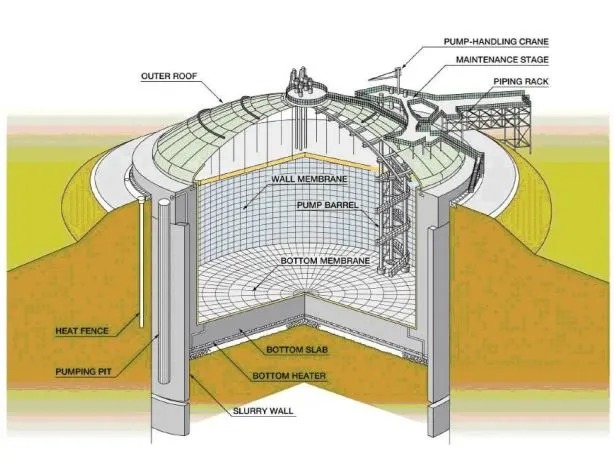

How in-ground LNG storage tanks work: Tank composition

1. Reinforced concrete tank cover

2. Steel roof

3. Suspended deck

4. Glass wool insulation

5. Non-CFC rigid polyurethane form (PUF) insulation

6. 18Cr-8Ni stainless steel membrane

7. Reinforced concrete side wall

8. Reinforced concrete cut-off wall

9. Side heater

10. Reinforced concrete bottom slab

11. Bottom heater

12. Gravel layer

Features of in-ground storage tank: Safety

In-ground LNG storage tanks are only partially visible from the outside of the terminal site making them difficult to be targeted by terrorists. Furthermore, since the LNG is stored below the ground surface, in the unlikely event of a terrorist attack or the concrete roof being destroyed by a projectile, the LNG would not leak onto the ground. Accordingly, the tanks are accredited with the European standard EN1473, making them the safest way to store LNG.

In an earthquake the seismic motion is not amplified for in-ground storage tanks when compared to above-ground structures making them safer in earthquake-prone regions. In order to make the tanks much safer from terrorist attacks, tank roofs can be lined with reinforced concrete or the roof of the tanks can be completely underground.

Features of in-ground storage tank: Environmentally friendly

The roofs of in-ground LNG storage tanks are the only part visible from the surface making the tanks a difficult target for terrorists. Moreover the tanks are not obtrusive to the surrounding environment, reducing the psychological impact that large tanks usually arouse.

In a further developed type of the tank,

Features of in-ground storage tank: Space-saving

In-ground storage tanks do not need to be surrounded by a dike and the legally required space between tanks as well as the necessary distance from items to be protected is relatively small allowing the tanks to conserve space.

Construction costs and time

It is now possible to construct large capacity in-ground storage tanks thanks to advances in technological development. Currently, Tokyo Gas constructs in-ground storage tanks sized from several thousand cubic meters to 200,000 cubic meters. Larger storage capacity makes for a lower per-unit cost. In-ground storage tanks are constructed at roughly the same cost as conventional above-ground storage tanks adding to the economical benefits. Construction time is also relatively the same for in-ground storage tanks.