FILTER

PRESS

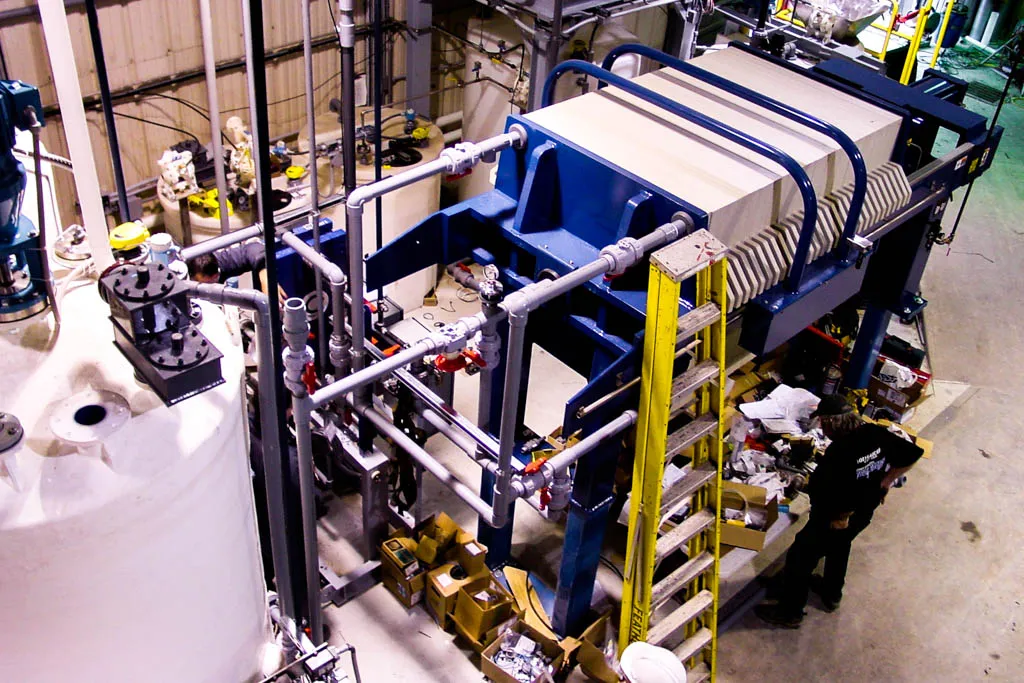

FILTER PRESS

L

LANTERN’s filter presses (FPS) are one of the most effective ways to dewater and compact liquid slurry. Depending on the nature of the slurry (or sludge), our FPS are typically capable of dewatering up to 30%–60% of the solids, producing clear filtrates while separated solids are removed from the press as a single, disposable cake. Our filters utilize recessed chamber plates that are concave on both sides and covered with a cloth filtration media. They are held together under pressure by a press frame and hydraulic system to create discreet filtration and solid holding chambers within the press. Liquid slurry is pumped into the press and fills these chambers, where the liquid and solids separate (dewater) via the pressure from the feed pump. Filtered liquid then passes through the filter cloth media and continues out of the press while solids are collected and concentrated in the recessed chambers. In many applications, FPS is one of most efficient technologies available today for liquid/solid separation.

Advantages:

-

- Reduces volume of sludge disposal

- Can be effective for zero liquid discharge (ZLD)

Disadvantages:

-

- Increases capital cost

- Large footprint

PROJECT BRIEFS

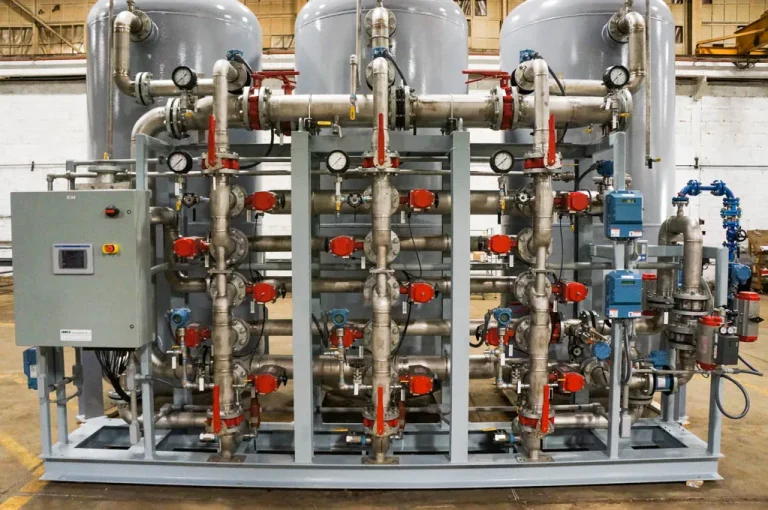

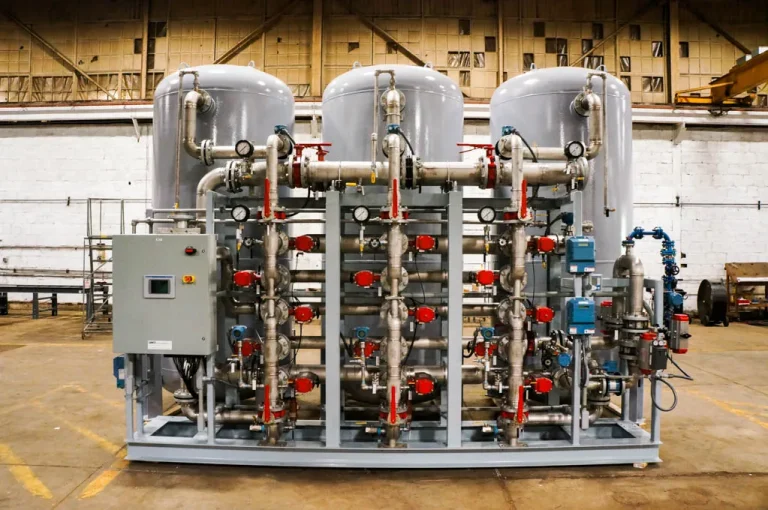

Major Petrochemical Plant Expands Plant Production with AMBERPACK™ Deionization System

In order to accommodate increasing production requirements at a prominent petrochemical plant in Mexico, the client consulted SAMCO to custom engineer a deionization system that could perform efficiently at a greater volume. Meeting the client’s needs, LANTEN provided a multifaceted solution to help the client effectively expand production while maintaining the water quality necessary for suitable boiler makeup water.

Oil Refinery Replaces Old Softening Equipment and Reduces Boiler Makeup Water Hardness with UPCORE™ Softening System

When an oil refinery in West Virginia needed to replace its softening equipment with a more efficient system, LANTERN helped the client install and run an effective UPCORE™ ion exchange system for minimal hardness and maximum results.

Specialty Metals Producer Optimizes Cadmium Recovery, Leveraging SAMCO Ion Exchange Technology for Wastewater Treatment

When a specialty metals producer in the Midwest needed an efficient solution for capturing cadmium from its wastewater streams, it looked to LANTERN for an ion exchange (IX) solution to maximize its resources.

Get to Know Binifox

Do you have any question? Feel free to contact us.

contact with us

Speak with our consultant

send email

info@lantern.energy

visit office

RM12, 20/F, HO KING COMM CTR,2-16 FAYUEN ST, MONGKOK KOWLOON HONGKONG